-

Fiberglass/FRP Pipeline Series

Fiberglass pipelines are also called GFRP or FRP pipelines, are a type of lightweight, high-strength, and corrosion-resistant non-metallic pipeline. FRP pipelines are made by wrapping layers of fiberglass with a resin matrix onto a rotating mandrel according to the required process, and laying a layer of quartz sand as a sand layer between the fibers at a far distance. The reasonable and advanced wall structure of the pipeline can fully exert the material’s function, increase rigidity while satisfying the prerequisite for use strength, and ensure the stability and reliability of the product. With its excellent resistance to chemical corrosion, lightweight and high strength, anti-scaling, strong seismic resistance, longer service life compared to conventional steel pipes, low comprehensive cost, quick installation, safety, and reliability, the fiberglass sand pipelines are widely accepted by users.

-

Walnut Shell Filter for Water Treatment

Walnut shell filter is the use of filtration separation principle developed successfully separation equipment, the use of oil-resistant filter material – special walnut shell as a filter medium, the walnut shell with large surface area, strong adsorption, large amount of pollution characteristics, remove the oil and suspended matter in the water.

Filtration, water flow from top to bottom, through the water distributor, filter material layer, water collector, complete filtration. Backwash, the agitator turns the filter material, water bottom up, so that the filter material is thoroughly cleaned and regenerated.

-

Fiber Ball Filter

Fiber ball filter is a new type of water quality precision treatment equipment in pressure filter. Previously in oily sewage reinjection treatment has been used in the double filter material filter, walnut shell filter, sand filter, etc. Especially in low permeability reservoir fine filtration technology can not meet the requirement of water injection in low permeability reservoir. The fiber ball filter can meet the standard of oily sewage reinjection. It is made of a special fiber silk synthesized from a new chemical formula. The main feature is the essence of the improvement, from the fiber filter material of the oil – wet type to the water – wet type. The high efficiency fiber ball filter body filter layer uses about 1.2m polyester fiber ball, raw water from top to bottom into the outflow.

-

Self-Cleaning Water Treatment Filter

Self-cleaning filter is a kind of water treatment equipment that uses the filter screen to directly intercept impurities in the water, remove suspended matter and particulate matter, reduce turbidity, purify water quality, reduce system dirt, bacteria and algae, rust, etc., in order to purify water quality and protect the normal work of other equipment in the system. It has the function of filtering raw water and automatically cleaning and discharging the filter element, and the uninterrupted water supply system can monitor the working status of the filter, with a high degree of automation.

-

Screw Sludge Dewatering Machine

The Screw sludge dewatering machine, also known as the screw sludge dewatering machine, sludge treatment equipment ,sludge extruder ,sludge extrator ,etc. is a kind of water treatment equipment widely used in municipal sewage treatment projects and industrial industries such as petrochemical, light industry, chemical fiber, paper making, pharmaceutical, leather and so on. In the early days, the screw filter was blocked because of the filter structure. With the development of spiral filtration technology, a relatively new filter structure appeared. The prototype of spiral filter equipment with dynamic and fixed ring filter structure — the cascade spiral sludge dehydrator began to be launched, which can well avoid the problems caused by the blockage, and therefore began to be promoted. The spiral sludge dehydrator has been widely used in many fields because of its characteristics of easy separation and non-clogging.

-

Air Flotation Equipment for Water Treatment

The air flotation machine is a water treatment equipment for the separation of solid and liquid by the solution air system producing a large number of micro bubbles in the water, so that the air is attached to the suspended particles in the form of highly dispersed micro bubbles, resulting in a state of density less than water. The air flotation device can be used for some impurities contained in the water body whose specific gravity is close to that of water and which are difficult to sink or float by their own weight. Bubbles are introduced into the water to adhere to the floc particles, thus greatly reducing the overall density of floc particles, and by using the rising speed of bubbles, forcing it to float, so as to achieve rapid solid-liquid separation.

-

Wastewater Treatment Integration Equipment

Integrated sewage treatment equipment refers to a series of sewage treatment equipment combined to form a compact, efficient treatment system to complete the treatment of sewage.

-

Inclined Tube Sedimentation Tank

Inclined tube sedimentation tank is an efficient combined sedimentation tank designed according to shallow sedimentation theory, also known as shallow sedimentation tank or inclined plate sedimentation tank. Many dense inclined tubes or inclined plates are set in the settling area to precipitate the suspended impurities in the water in the inclined plates or inclined tubes.

-

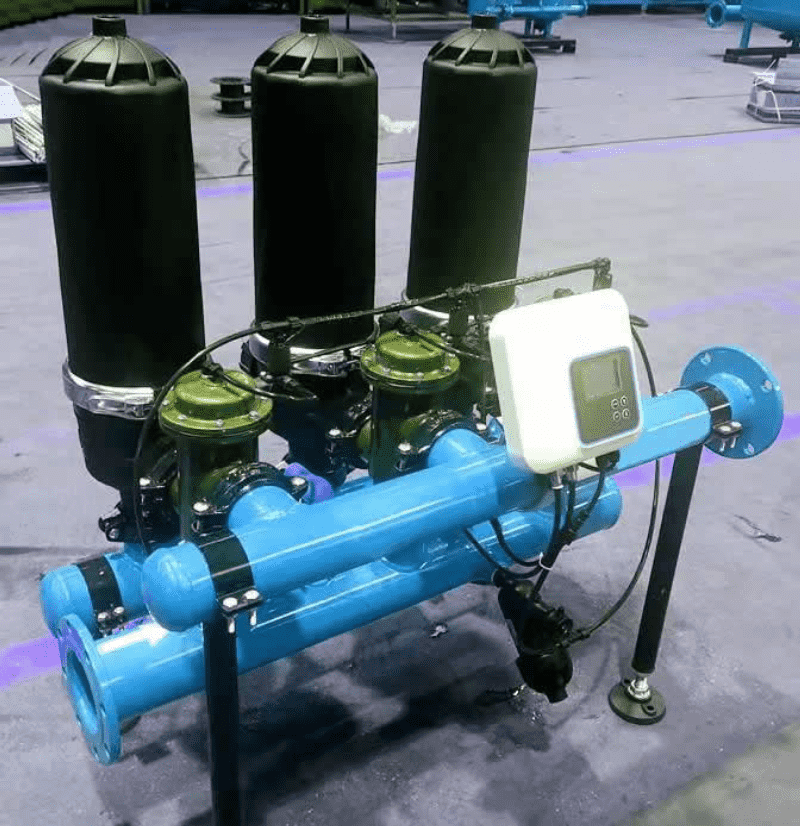

Laminated Filter

Laminated filters, thin sheets of a specific color of plastic with a number of grooves of a certain micron size etched on either side. A stack of the same pattern is pressed against a specially designed brace. When pressed by a spring and liquid pressure, the grooves between the sheets cross to create a deep filter unit with a unique filter channel. The filter unit is housed in a super strong performance engineering plastic filter cylinder to form the filter. When filtering, the filter stack is pressed by spring and fluid pressure, the greater the pressure difference, the stronger the compression force. Ensure self – locking efficient filtration. The liquid flows from the outer edge of the laminate to the inner edge of the laminate through the groove, and passes through 18 ~ 32 filtration points, thus forming a unique deep filtration. After the filter is finished, manual cleaning or automatic backwashing can be done by loosening between the sheets manually or hydraulically.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur