-

Walnut Shell Filter for Water Treatment

Walnut shell filter is the use of filtration separation principle developed successfully separation equipment, the use of oil-resistant filter material – special walnut shell as a filter medium, the walnut shell with large surface area, strong adsorption, large amount of pollution characteristics, remove the oil and suspended matter in the water.

Filtration, water flow from top to bottom, through the water distributor, filter material layer, water collector, complete filtration. Backwash, the agitator turns the filter material, water bottom up, so that the filter material is thoroughly cleaned and regenerated.

-

Fiber Ball Filter

Fiber ball filter is a new type of water quality precision treatment equipment in pressure filter. Previously in oily sewage reinjection treatment has been used in the double filter material filter, walnut shell filter, sand filter, etc. Especially in low permeability reservoir fine filtration technology can not meet the requirement of water injection in low permeability reservoir. The fiber ball filter can meet the standard of oily sewage reinjection. It is made of a special fiber silk synthesized from a new chemical formula. The main feature is the essence of the improvement, from the fiber filter material of the oil – wet type to the water – wet type. The high efficiency fiber ball filter body filter layer uses about 1.2m polyester fiber ball, raw water from top to bottom into the outflow.

-

Self-Cleaning Water Treatment Filter

Self-cleaning filter is a kind of water treatment equipment that uses the filter screen to directly intercept impurities in the water, remove suspended matter and particulate matter, reduce turbidity, purify water quality, reduce system dirt, bacteria and algae, rust, etc., in order to purify water quality and protect the normal work of other equipment in the system. It has the function of filtering raw water and automatically cleaning and discharging the filter element, and the uninterrupted water supply system can monitor the working status of the filter, with a high degree of automation.

-

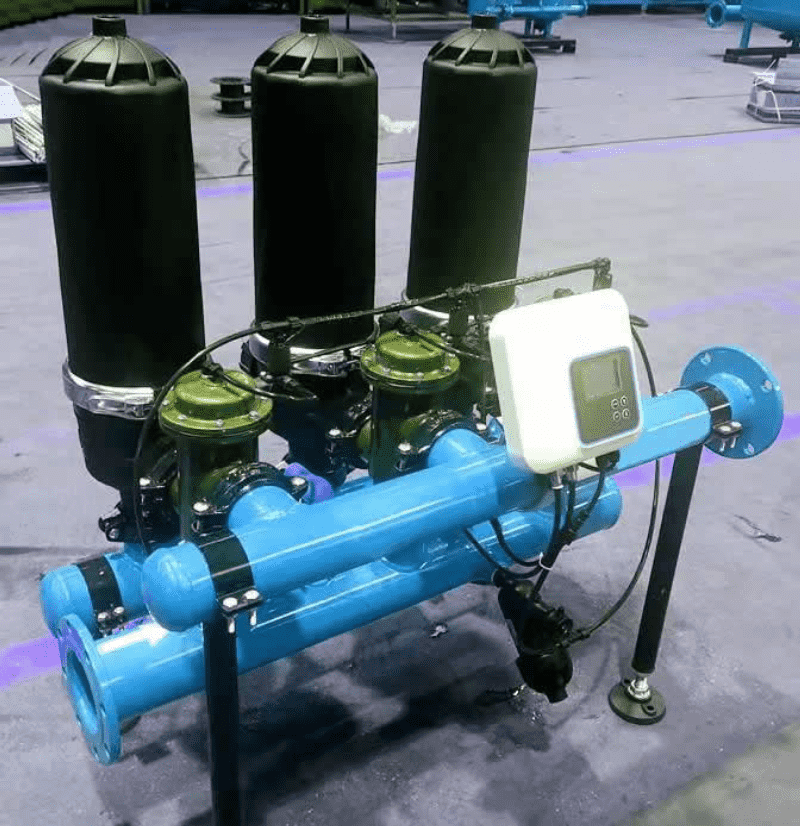

Laminated Filter

Laminated filters, thin sheets of a specific color of plastic with a number of grooves of a certain micron size etched on either side. A stack of the same pattern is pressed against a specially designed brace. When pressed by a spring and liquid pressure, the grooves between the sheets cross to create a deep filter unit with a unique filter channel. The filter unit is housed in a super strong performance engineering plastic filter cylinder to form the filter. When filtering, the filter stack is pressed by spring and fluid pressure, the greater the pressure difference, the stronger the compression force. Ensure self – locking efficient filtration. The liquid flows from the outer edge of the laminate to the inner edge of the laminate through the groove, and passes through 18 ~ 32 filtration points, thus forming a unique deep filtration. After the filter is finished, manual cleaning or automatic backwashing can be done by loosening between the sheets manually or hydraulically.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur