Fiberglass reinforced plastic process pipes / FRP process pipes

Fiberglass reinforced plastic process pipes / FRP process pipes Characteristics

1.The fiberglass reinforced plastic (FRP) process pipes have high resistance to corrosion as different types of anti-corrosion resins can be selected for lining, suitable for various types of acids, alkalis, salts, oils, seawater, and organic solvents.

2.The operating temperature of FRP process pipes is below 150℃, making it suitable for use in different types of soils. It is applicable for conveying drinking water, sewage, seawater, circulating water pipelines in power plants, conveying corrosive media in chemical enterprises, oil and gas transportation, agricultural irrigation, etc.

3.The FRP process pipes are lightweight, easy to maintain, and highly durable.

4.The installation of FRP pipes is easy as there are no technical limitations on the length of the pipes. However, due to transportation considerations, the length is generally within 12m to reduce the number of joints. The lightweight of FRP pipelines also enables manual or light installation equipment to be used for convenient and quick installation.

5.The FRP pipelines have strong adaptability as they are available in standard sizes ranging from 50mm to 4200mm. The long-term pressure resistance of the pipeline is generally within 1.6Mpa, but can reach up to 6.4Mpa or more depending on the user's special requirements.

6.The FRP process pipes have higher transport efficiency as the inner wall of the pipeline is smooth, with a roughness coefficient N≤0.0084. Compared with traditional materials of the same diameter, the FRP pipes have higher hydraulic capacity, which saves pump energy and prolongs the life of the project and equipment.

7.The FRP process pipes have low permeation rate due to their good sealing connection and longer pipe length when compared with traditional materials.

Model and Specifications of FRP process pipelines

(*Note: The specifications of the pipe is the minimum wall thickness of the ventilation pipe. Other requirements can be specified by the customer)

| DN(mm) | 50 | 65 | 80 | 100 | 125 | 150 | 175 | 200 | 280 | 300 | 350 | 400 | 450 | ||||||||||

| Standard thickness | T(mm) | 3 | 3 | 3 | 3 | 3.5 | 3.5 | 3.5 | 3.5 | 4 | 4 | 4 | 4 | 4.5 | |||||||||

| Standard length | L(mm) | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 12 | 12 | 12 | 12 | 12 | |||||||||

| DN(mm) | 500 | 550 | 600 | 700 | 800 | 900 | 1000 | 1200 | 1400 | 1500 | 1600 | 1800 | 2000 | ||||||||||

| Standard thickness | T(mm) | 4.5 | 4.5 | 5 | 6 | 6 | 7 | 8 | 8 | 9 | 10 | 10 | 11 | 12 | |||||||||

| Standard length | L(mm) | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | |||||||||

| DN(mm) | 2200 | 2400 | 2500 | 2600 | 2800 | 3000 | 3200 | 3400 | 3500 | 3800 | 4000 | 4200 | |||||||||||

| Standard thickness | T(mm) | thickness is determined by design | |||||||||||||||||||||

| Standard length | L(mm) | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||||||||||

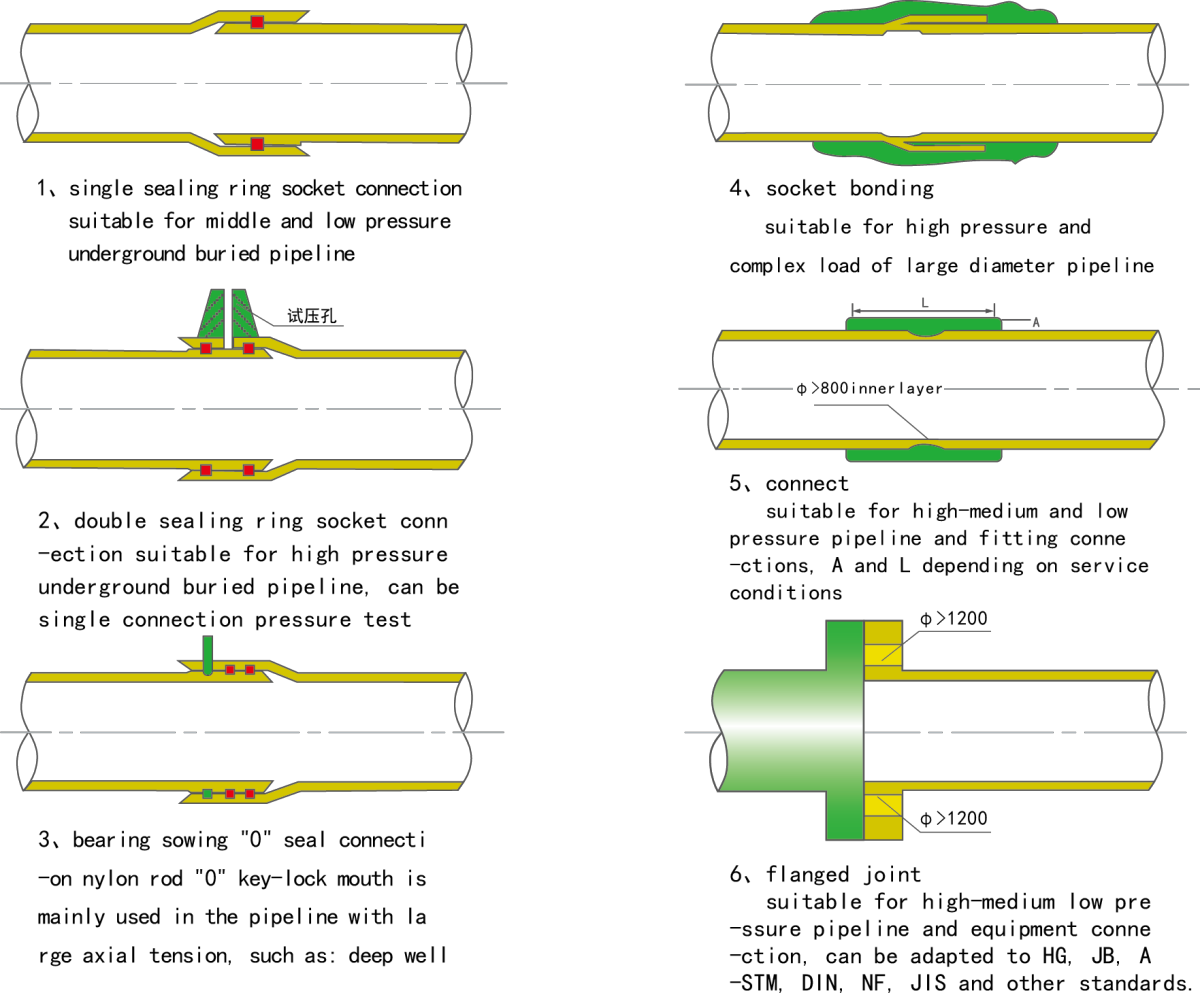

Connection and Installation of FRP pipes

The connection of the quartz sand pipeline adopts the socket-type sealing connection method, which is fast, accurate, time-saving, and labor-saving. In special circumstances, flange connection or other forms of connection can also be used. The FRP pipeline connection consists of two parts: a special rubber inner lining and a glass fiber reinforced polyvinyl acetate outer wall. The FRP pipeline adopts full surface thermosetting cross-linking technology, which has reliable mechanical performance, corrosion resistance, and sealing performance. In general, the socket-type sealing connection can ensure fast, accurate, time-saving, and labor-saving connection. Additionally, flange connection or other methods can also be utilized.

FRP Cable Conduit / FRP Cable Casing

Fiberglass cable conduit is a category of TOPTION FRP piping products, which uses resin as the matrix and continuous FRP and its fabric as the reinforcing material. It is a type of conduit formed using computer-controlled winding or extrusion processes.

Fiberglass Reinforced Plastic Cable Conduit (FRP Cable Conduit ) Characteristics

1) High strength, used for straightening under the roadway without a protective layer, which can accelerate the construction progress.

2) Good toughness, able to resist external pressure and damage caused by foundation settlement.

3) Good electrical insulation, flame retardant, and heat-resistant properties, can be used long-term at a high temperature of 130 degrees without deformation.

4) Corrosion-resistant, with long service life, able to resist corrosion from various corrosive media such as acid, alkali, salt, and organic solvents, and its service life can reach 50 years.

5) Smooth inner wall, does not scratch cables. Rubber-sealed joints are convenient for installation and connection, and can adapt to thermal expansion and contraction.

6) Small specific gravity, light weight, can be lifted by one person and installed by two people, greatly reducing the construction period and installation costs. At the same time, FRP cable conduit avoids the problem of long exposure time caused by road excavation, affecting urban traffic order, etc.

7) No electric corrosion, non-magnetic. Unlike magnetic materials such as steel pipes, it will not cause cable heating damage due to eddy currents.

8) Wide application range, FRP cable conduits are used as protective tubes for buried cables, as well as in high-demand scenarios such as cable bridges and crossings. The use of matching professional pipe pillows can form a multi-layer and multi-column multi-conduit arrangement

FRP Sand Pipe Parameter Form(*Note: Our product’s length is 12 meters)

| nominal

stiffness |

2500Pa stiffness | 3750Pa stiffness | 5000Pa stiffness | 7500Pa stiffness | ||||||||||||

| 0.25

MPa |

0.6

MPa |

1.0

MPa |

0.25

MPa |

0.6

MPa |

1.0

MPa |

0.25

MPa |

0.6

MPa |

1.0

MPa |

1.6

MPa |

0.25

MPa |

0.6

MPa |

1.0

MPa |

1.6

MPa |

1.0

MPa |

1.6

MPa |

|

| 300 | 5.00 | 5.00 | 5.00 | 5.00 | 5.00 | 5.00 | 5.40 | 5.30 | 5.30 | 6.10 | 6.10 | 6.00 | 5.80 | 6.50 | 6.30 | |

| 400 | 5.70 | 5.70 | 5.50 | 6.30 | 6.30 | 6.30 | 6.80 | 6.80 | 6.60 | 8.00 | 8.00 | 7.50 | 7.40 | 8.30 | 8.10 | |

| 500 | 6.90 | 6.70 | 6.60 | 7.70 | 7.70 | 7.50 | 8.50 | 8.40 | 8.00 | 9.70 | 9.50 | 9.10 | 8.80 | 10.10 | 9.80 | |

| 600 | 8.20 | 7.70 | 7.70 | 9.20 | 9.10 | 8.50 | 10.20 | 9.70 | 9.30 | 11.50 | 11.40 | 10.70 | 10.50 | 11.70 | 11.50 | |

| 700 | 9.50 | 8.80 | 8.60 | 10.80 | 10.30 | 10.00 | 12.00 | 11.30 | 10.70 | 13.60 | 13.00 | 12.40 | 11.90 | 13.50 | 13.10 | |

| 800 | 10.90 | 10.20 | 9.90 | 12.40 | 11.50 | 11.00 | 13.70 | 13.20 | 12.10 | 15.80 | 14.70 | 14.00 | 13.50 | 15.20 | 14.80 | |

| 900 | 12.20 | 11.40 | 10.80 | 14.00 | 12.90 | 12.30 | 15.50 | 14.40 | 13.50 | 17.90 | 16.90 | 15.60 | 15.10 | 17.10 | 16.60 | |

| 1000 | 13.50 | 12.40 | 11.90 | 15.60 | 14.20 | 13.50 | 17.30 | 16.00 | 14.90 | 20.00 | 18.50 | 17.30 | 16.50 | 18.80 | 18.20 | |

| 1200 | 16.00 | 14.70 | 14.00 | 18.50 | 16.80 | 16.20 | 21.00 | 19.10 | 17.80 | 23.70 | 22.00 | 20.30 | 19.70 | 22.40 | 21.60 | |

| 1400 | 18.20 | 17.00 | 16.00 | 21.50 | 19.60 | 18.50 | 24.00 | 22.00 | 20.30 | 27.40 | 25.40 | 23.40 | 22.60 | 26.40 | 25.20 | |

| 1600 | 21.30 | 19.20 | 18.30 | 24.10 | 22.20 | 21.00 | 27.60 | 24.80 | 23.00 | 22.40 | 31.30 | 29.00 | 26.60 | 25.80 | 29.80 | 28.40 |

| 1800 | 23.30 | 21.50 | 20.50 | 27.20 | 25.00 | 23.50 | 30.80 | 27.60 | 25.80 | 25.20 | 35.00 | 32.40 | 29.90 | 29.00 | 33.10 | 31.40 |

| 2000 | 25.90 | 24.00 | 22.50 | 30.00 | 27.50 | 16.00 | 34.00 | 30.50 | 28.50 | 27.70 | 38.70 | 36.00 | 33.00 | 31.80 | 36.60 | 34.80 |

| 2200 | 28.50 | 26.10 | 24.70 | 32.80 | 30.00 | 28.50 | 37.00 | 33.50 | 31.20 | 30.40 | 43.00 | 39.30 | 36.20 | 35.00 | 40.20 | 38.10 |

| 2400 | 31.10 | 28.40 | 26.80 | 36.00 | 32.80 | 30.90 | 40.30 | 36.40 | 34.00 | 33.20 | 46.20 | 42.80 | 39.20 | 35.00 | 44.00 | 41.50 |

| 2600 | 34.00 | 30.70 | 29.00 | 39.00 | 35.20 | 33.40 | 44.00 | 39.40 | 36.50 | 35.80 | 50.40 | 48.00 | 42.40 | 41.20 | 47.50 | 45.50 |

Application Fields of FRP Cable Conduit

Fiberglass cable conduits are suitable for protecting cables in various environments, including power and communication cables. They are especially useful in special environments such as crossing traffic thoroughfares, rivers and bridges, where their construction is simple, and their high strength and other excellent characteristics can be fully utilized. They are widely used in the infrastructure construction fields of power, communication, transportation, and civil aviation airports.

Specifications and Dimensions of Fiberglass Cable Conduit

| Type Specification | D | T | D1 | D2 | D3 | T | S | S1 | Z | L | weight kg/m |

| BBB-50/5 | 50 | 5 | 60 | 68 | 78 | 5 | 110 | 80 | 83 | 4000 | 1.8 |

| BBB-70/5 | 70 | 5 | 80 | 88 | 98 | 5 | 110 | 80 | 83 | 4000 | 2.3 |

| BBB-80/5 | 80 | 5 | 90 | 98 | 108 | 5 | 110 | 80 | 83 | 4000 | 2.7 |

| BBB-100/5 | 100 | 5 | 110 | 118 | 125 | 5 | 130 | 80 | 83 | 4000 | 3.3 |

| BBB-100/8 | 100 | 8 | 116 | 124 | 140 | 8 | 130 | 80 | 83 | 4000 | 5.4 |

| BBB-125/5 | 125 | 5 | 135 | 143 | 153 | 5 | 130 | 100 | 105 | 4000 | 3.8 |

| BBB-150/3 | 150 | 0 | 156 | 164 | 170 | 3 | 160 | 100 | 105 | 4000 | 2.8 |

| BBB-150/5 | 150 | 5 | 160 | 168 | 178 | 5 | 160 | 100 | 105 | 4000 | 4.8 |

| BBB-150/8 | 150 | 8 | 166 | 175 | 190 | 8 | 160 | 100 | 105 | 4000 | 758 |

| BBB-150/10 | 150 | 10 | 170 | 178 | 198 | 10 | 160 | 100 | 105 | 4000 | 9.5 |

| BBB-175/10 | 175 | 10 | 195 | 203 | 223 | 10 | 160 | 100 | 105 | 4000 | 11.0 |

| BBB-200/10 | 200 | 10 | 220 | 228 | 248 | 10 | 180 | 120 | 125 | 4000 | 12.4 |

| BBB-200/12 | 200 | 12 | 224 | 232 | 257 | 12 | 180 | 120 | 125 | 4000 | 15.0 |