Introduction for integrated wastewater treatment equipment

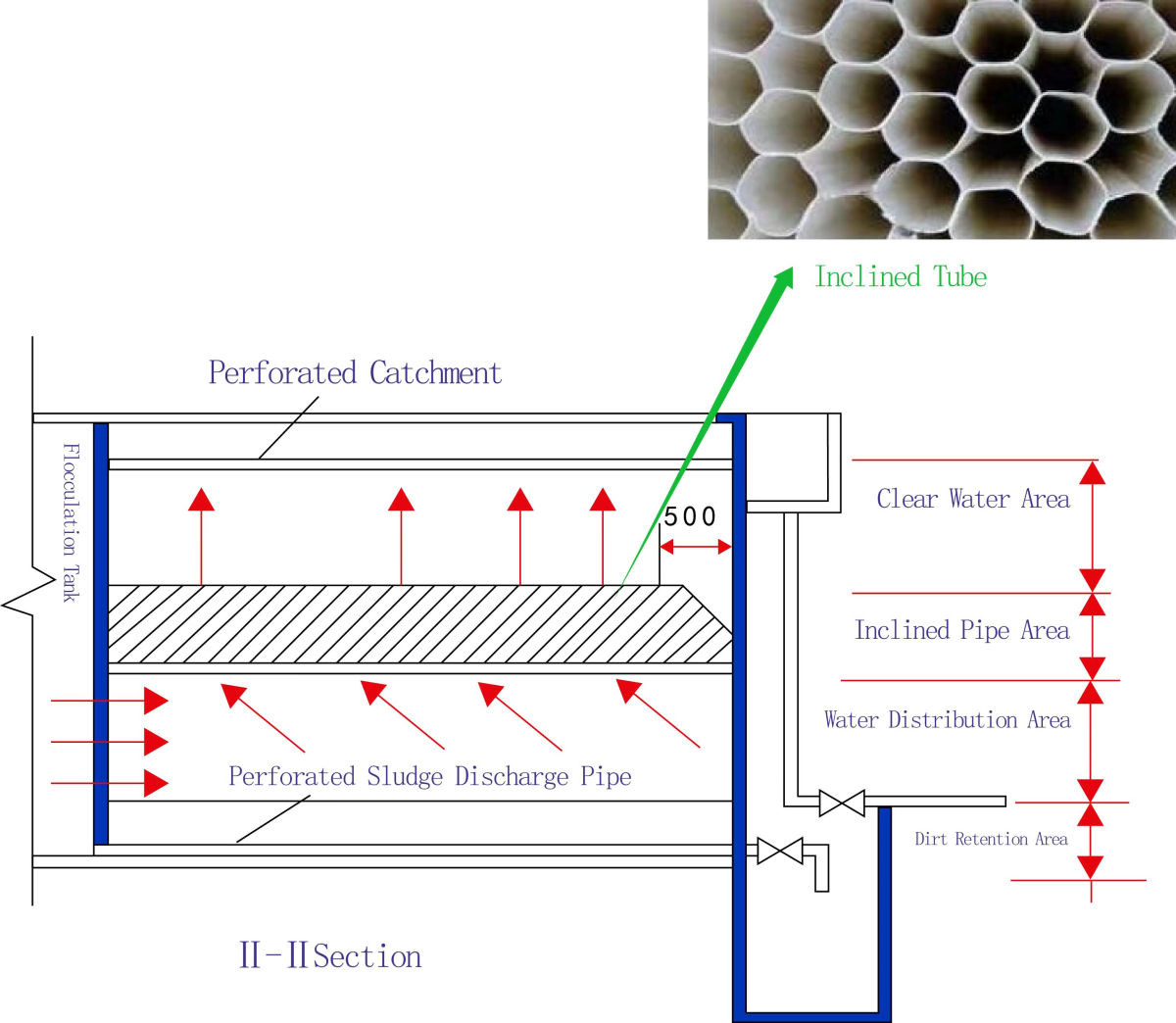

Inclined tube sedimentation tank is an efficient combined sedimentation tank designed according to shallow sedimentation theory, also known as shallow sedimentation tank or inclined plate sedimentation tank. Many dense inclined tubes or inclined plates are set in the settling area to precipitate the suspended impurities in the water in the inclined plates or inclined tubes. The water flows upward along the inclined plates or inclined tubes, and the separated sludge slides down to the bottom of the tank under the action of gravity, and then is concentrated and discharged. Such basin can increase the precipitation efficiency by 50-60% and increase the processing capacity by 3-5 times over the same area. The slanted tube sedimentation with different flow rates can be designed according to the test data of the original wastewater, and flocculant should be added in general.

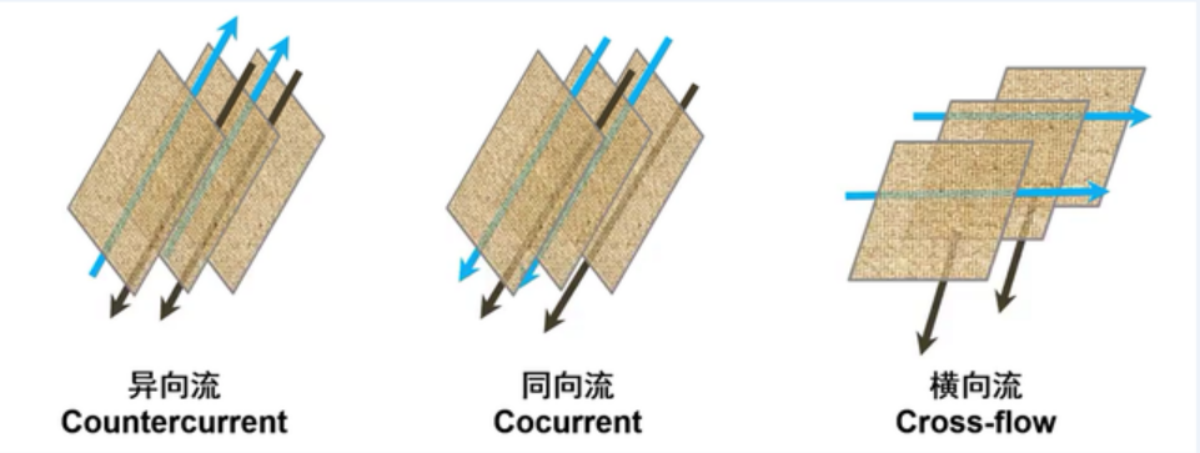

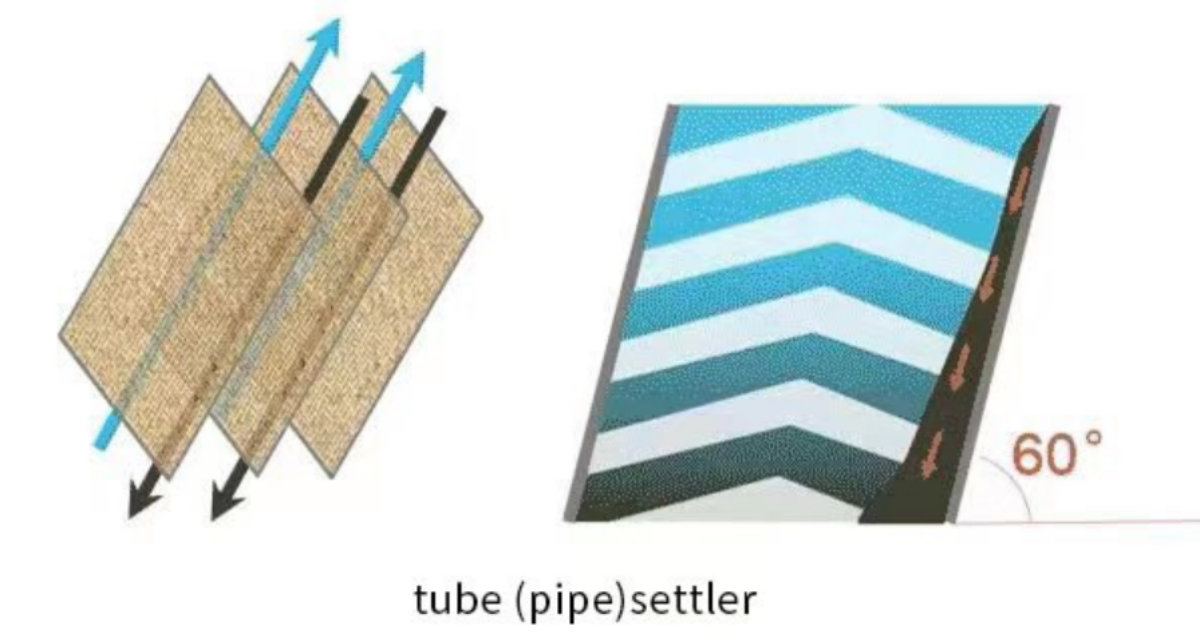

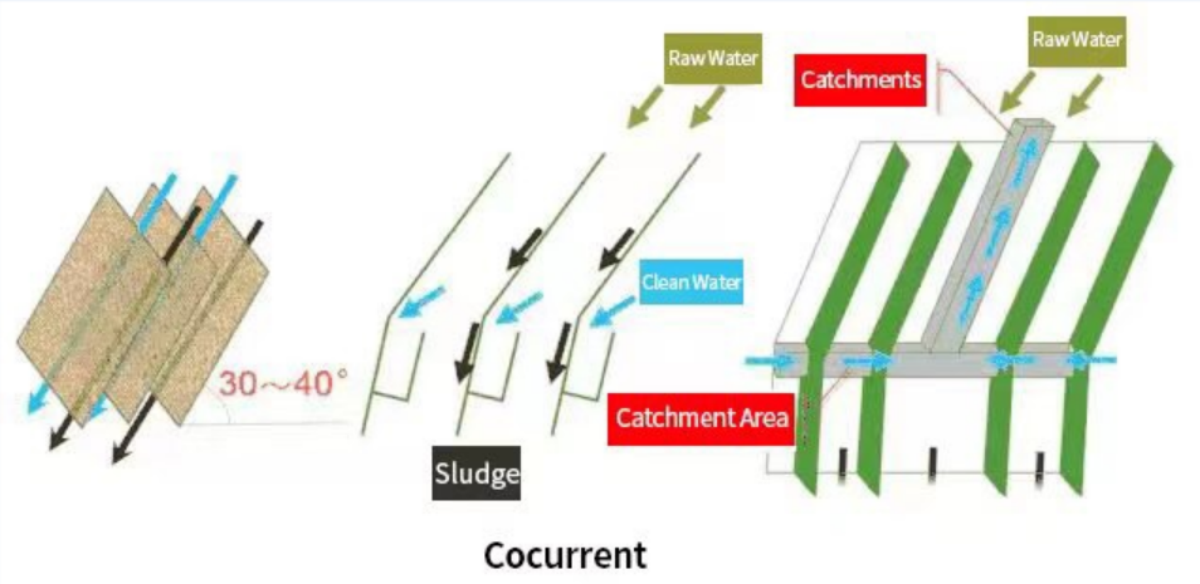

According to the direction of their mutual movement, they can be divided into three different separation modes: Reverse (different) Flow, Same Flow and Lateral Flow. Between each two parallel inclined plates (or parallel tubes) is equivalent to a very shallow sedimentation tank.

First of all, the inclined tube sedimentation tank of the different flow (reverse flow), the water flows from the bottom up, and the precipitated sludge slides down, the inclined plate is generally placed at an Angle of 60°, so as to facilitate the slide of the precipitated sludge. As the water flows through the inclined plate, the particles sink and the water becomes clear. In the same flow inclined plate (tube) sedimentation tank, the direction of the water flow from the top down, and the sliding direction of the precipitated sludge is the same, so it is called the same flow. Because the downward flow of water promotes the slide of sediment sludge, the inclined Angle of the inclined plate of the same flow sedimentation tank is generally 30°~40°.

The advantages of inclined tube settling tank

1) The laminar flow principle is used to improve the processing capacity of the sedimentation tank or slanted tube settling tank.

2) Shorten the settling distance of particles, thus shortening the precipitation time;

3) The precipitation area of tilted tube sedimentation basin is increased, thus improving the treatment efficiency.

4) High removal rate, short residence time and small footprint.

The inclined tube sedimentation tank/ slanted tube settling tank uses the theory of shallow tank, the flow rate can reach 36m3/(m2.h), which is 7-10 times higher than the processing capacity of the general sedimentation tank. It is a new kind of efficient sedimentation equipment.

Application Field

1, Electroplating Industry: wastewater containing a variety of metal ions mixed wastewater, Ming, copper, iron, zinc, nickel removal rate are above 90%, general electroplating wastewater after treatment can meet the discharge standards.

2, Coal mine, mining area: wastewater can make turbidity in 500-1500 mg/L to 5 mg/L.

3, Dyeing, dyeing and other industries: wastewater color removal rate of 70-90%, COD removal of 50-70%.

4, Tanning, food and other industries: wastewater removal of a large number of organic matter, COD removal rate of 50-80%, the removal rate of impurities solid more than 90%.

5. Chemical industry: the COD removal rate of wastewater is 60-70%, the chroma removal is 60-90%, and the suspended matter reaches the discharge standard.

Parameter

| Parameters of Inclined Tube Sedimentation Tank | ||||||

| Model | Capacity (m3/h) |

Size (mm) | Input(DN) | Output(DN) | Weight(MT) | Operating Weight(MT) |

| TOP-X5 | 5 | 2800*2200*H3000 | DN50 | DN65 | 3 | 15 |

| TOP-X10 | 10 | 4300*2200*H3500 | DN65 | DN80 | 4.5 | 25 |

| TOP-X15 | 15 | 5300*2200*H3500 | DN65 | DN80 | 5 | 30 |

| TOP-X20 | 20 | 6300*2200*H3500 | DN80 | DN100 | 5.5 | 35 |

| TOP-X25 | 25 | 6300*2700*H3500 | DN80 | DN100 | 6 | 40 |

| TOP-X30 | 30 | 7300*2700*H3500 | DN100 | DN125 | 7 | 50 |

| TOP-X40 | 40 | 7300*3300*H3800 | DN100 | DN125 | 9 | 60 |

| TOP-X50 | 50 | 9300*3300*H3800 | DN125 | DN150 | 12 | 80 |

| TOP-X70 | 70 | 12300*3300*H3800 | DN150 | DN200 | 14 | 110 |