Toption Machinery is a leading manufacturer of water treatment equipment. Let’s take a look at Toption Machinery’s technological process of reverse osmosis equipment.

The quality of raw water is crucial for reverse osmosis equipment, because if the raw water is surface water or groundwater, it will contain some soluble or insoluble organic and inorganic substances. Although reverse osmosis equipment can effectively intercept these impurity elements, but the main function of reverse osmosis is used for desalination, if the pretreatment process of reverse osmosis is not perfect, then the inlet water quality has too high turbidity, suspended substances, hardness, etc., it will accumulate on the surface of the reverse osmosis membrane, causing the phenomenon of scaling on the surface, blocking the water flow channel, resulting in increased pressure difference of the membrane component, decreased water production, and reduced salt removal rate, which will directly harm the service life cycle of the reverse osmosis equipment.

Reverse osmosis membranes have different chemical stability due to a variety of different types of materials. The tolerance of PH, residual chlorine, water temperature, microorganisms and other chemical substances in the inlet water quality of reverse osmosis equipment is also very different, and the turbidity of the inlet water, the content of suspended matter and colloidal substances must be strictly controlled and mastered. The lower the pollution index FI, the better. Reverse osmosis equipment needs to be formulated and implemented in strict accordance with the inlet water quality standards.

Therefore, it is necessary to specify the specific requirements of reverse osmosis equipment for inlet water, and different raw water quality needs to pass the corresponding pretreatment process before it can be connected to the reverse osmosis equipment system.

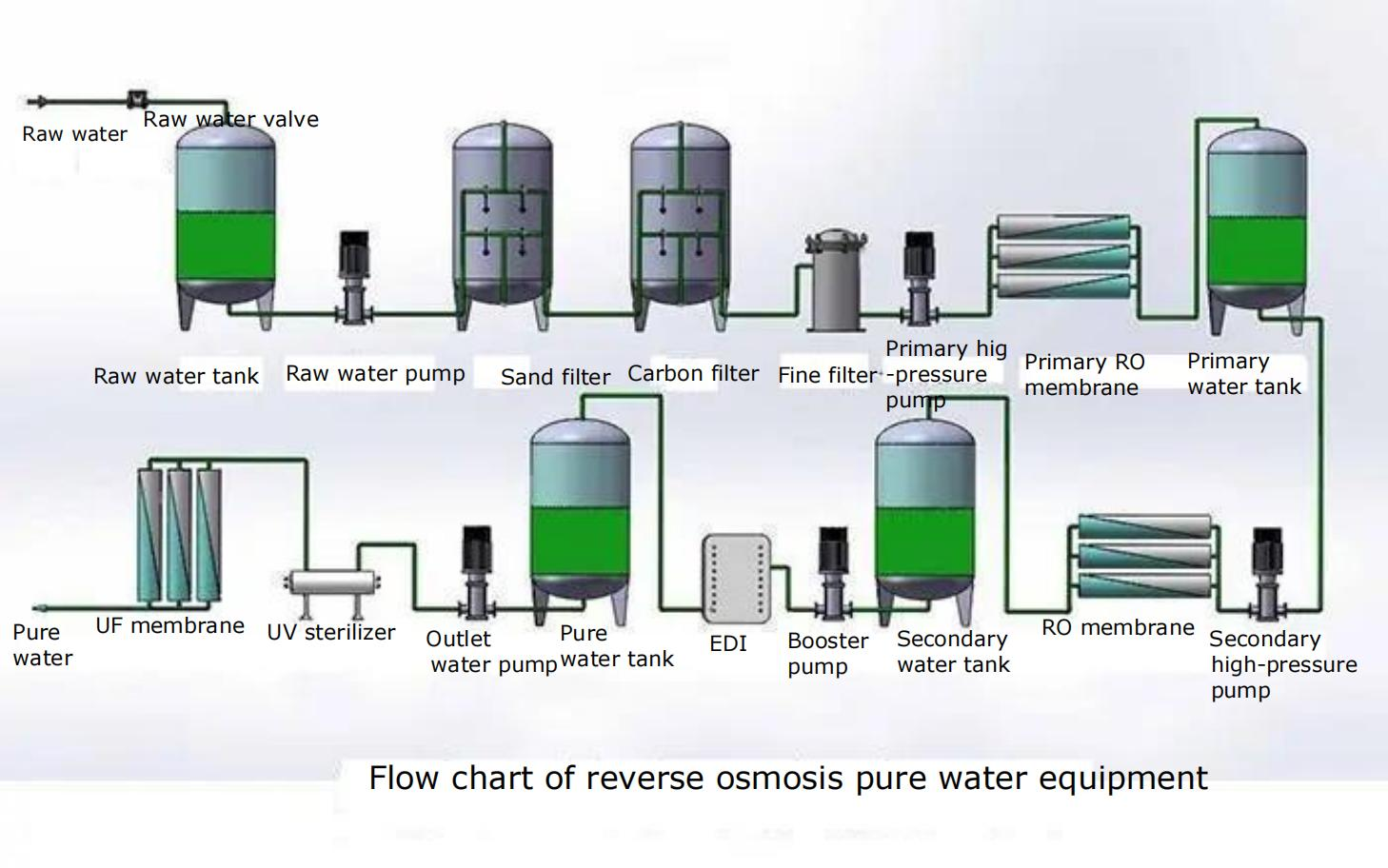

1. Preprocessing

Before reverse osmosis water treatment equipment, pretreatment of water is required. This includes steps such as filtration, dosing, etc. Through pretreatment, the content of suspended solids and organic matter in the water can be reduced, thereby protecting the reverse osmosis membrane and extending the life of the equipment.

2. Reverse osmosis

Reverse osmosis is the core process of reverse osmosis water treatment equipment. Under the action of the reverse osmosis membrane, salts and impurities in the water are filtered out, and only pure water molecules are passed through.

Reverse osmosis membrane is a high-precision filtration membrane that can filter out particles larger than 0.0001 microns in diameter, so it can effectively remove salts and microorganisms from water.

3. Membrane cleaning

Reverse osmosis membranes accumulate a large amount of impurities after long-term use and need to be cleaned regularly. When cleaning, it is necessary to connect the two ends of the reverse osmosis membrane to the cleaning liquid and the discharge pipe, and then pass the cleaning liquid through the reverse osmosis membrane to remove impurities on the membrane.

4. Secondary processing

After reverse osmosis treatment, the purity of the water has been greatly improved, but there may still be some trace impurities and microorganisms. In order to further improve the purity of the water, secondary treatment of the water is required. Secondary treatment can use activated carbon filtration, ultraviolet disinfection and other methods to ensure the safety and purity of water.

5. Storage

Finally, the treated water needs to be stored. Storage equipment can be selected according to needs, including storage buckets, water tanks, etc. To ensure the quality of the water, storage equipment needs to be cleaned and disinfected regularly.

The above is the process flow of reverse osmosis water treatment equipment. Through scientific and reasonable process flow, reverse osmosis water treatment equipment can effectively remove impurities and salts in water, improve the purity of water, and protect people’s health. Toption Machinery’s reverse osmosis equipment has been recognized and praised by many customers for its advanced technology, high-quality materials, stable performance and good after-sales service. In the future, Toption Machinery will continue to increase research and development efforts, continuously improve product performance and services, and provide customers with more high-quality softened water treatment equipment, thereby promoting the development of China’s water treatment equipment industry.

If you have any questions, please contact us.

Post time: Jun-27-2023