Fiberglass Septic Tank series

FRP septic tank refers to a device specially used to treat domestic sewage, which is made of synthetic resin as the base material and reinforced with fiberglass. FRP septic tank is mainly suitable for domestic sewage purification treatment equipment in industrial enterprises' living quarters and urban residential areas. It plays a positive role in intercepting and precipitating large particles and impurities in sewage, preventing sewage pipeline blockage, and reducing pipeline burial depth. The fiberglass septic tank utilizes the principles of precipitation and anaerobic fermentation to remove suspended organic matter in domestic sewage. The FRP septic tank is designed with baffles, and the holes on the baffles are staggered up and down, which makes it difficult to form short flow and greatly improves reaction efficiency.Currently, domestic sewage pollution is increasingly severe. Based on summarizing and introducing foreign domestic sewage treatment processes, this product combines company research and development achievements and engineering practices. It adopts high polymer composite materials and factory production, and is an efficient, energy-saving, lightweight, and inexpensive domestic sewage treatment equipment. It has successfully replaced traditional brick and steel septic tanks that pollutes underground water quality and affects surrounding buildings' safety due to leakage and poor operating conditions. The product uses the gravity flow of water, requires no external power or operating costs, saves energy, and is easy to manage, with good social, environmental, and economic benefits.

FRP Septic Tank Construction Operations

1.Excavation of foundation trench

2.Foundation and installation

3.Backfilling of foundation trench

4.During construction, strict compliance with the current engineering construction and acceptance specifications is required.

When installing septic tanks in parallel, the following principles should be followed:

(1)When the volume of the septic tank exceeds 50m³, two septic tanks should be installed in parallel;

(2)It is advisable to use two septic tanks of the same size

(3)The installation elevation of the two septic tanks should be the same;

(4) The inlet and outlet of the two septic tanks should each have their own inspection well;The angle of the inlet/outlet pipeline connection can be adjusted according to the site conditions, but the angle should not be less than 90 degrees.

FRP Valveless Filter Tank Series

Adaptation Conditions:

(1)The water before filtration should be subjected to coagulation and sedimentation or clarification treatment, and the turbidity should be below 15 mg/L. The turbidity of the filtered water should be below 5 mg/L.

(2)The calculated strength of the foundation should be 10 tons/square meter. If the strength of the foundation is less than 10 tons/square meter, it should be recalculated.

(3)Suitable for areas with seismic intensity of 8 or below.

(4)Freezing prevention is not considered in this atlas. Appropriate measures should be taken according to specific conditions if there is a possibility of freezing.

(5)This filter requires that the pre-treatment structure must ensure a certain water head at the outlet, and the waste water should be discharged smoothly during flushing.

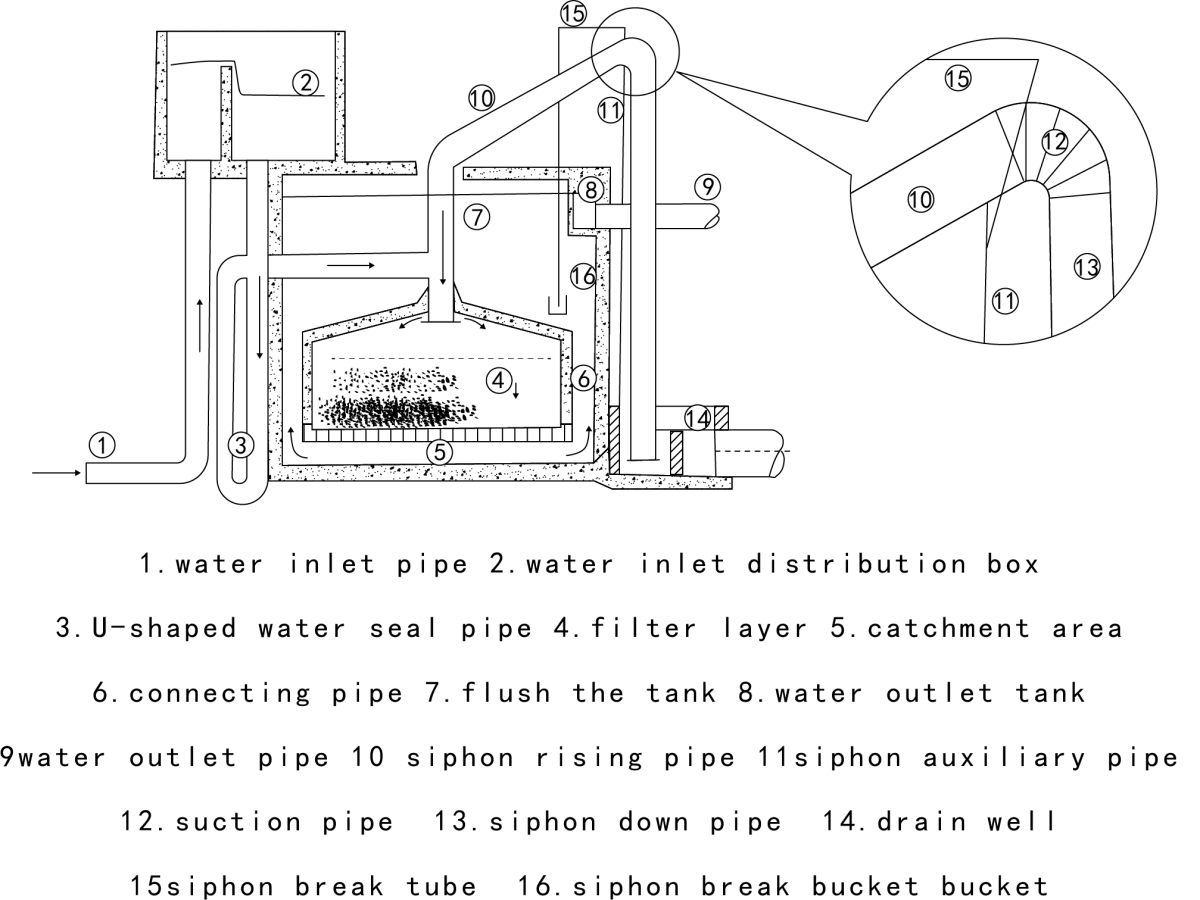

FRP Valveless Filter Tank Working Principle:

Sea water and fresh water enter the top high-level water tank of the filter tower through fiberglass/FRP pipes, and then enter the filter through FRP U-shaped pipes that are self-pressurized and equalized by the high-level water tank. After evenly spraying on the surrounding spray plate, the water passes through the sand filter layer for filtration, and then the filtered water is concentrated in the collecting area, and then pressurized through the connecting pipe to the clear water tank. When the clear water tank is full, the water flows out through the outlet pipe into the water purchase pool or nursery and breeding workshop. When the filter layer continuously intercepts water impurities and suspended solids that block the filter, the water is forced to enter the top of the siphon riser. At this time, the water falls through the siphon auxiliary pipe, and the air in the descending pipe of the siphon is carried away by the suction pipe. When a certain vacuum is formed in the siphon pipe, the siphon effect occurs, driving the water in the clear water tank to enter the collecting area through the connecting pipe and flow from bottom to top through the sand filter layer and the siphon pipe for backwashing. The impurities and dirt trapped in the filter layer are siphoned into the sewage tank for discharge. When the water level in the clear water tank drops to the point where it breaks the siphon pipe, air enters the siphon pipe and breaks the siphon effect, stopping the backwashing of the filter tower and entering the next cycle of filtration. The backwashing time depends on the quality of the water. When the water quality is good on sunny days, the backwashing can be performed once every 2-3 days. When the water quality is turbid due to wind, the backwashing can be performed once every 8-10 hours. The backwashing time is 5-7 minutes each time, and the backwashing water volume depends on the filtering capacity of the filter tower and ranges from 5-15 cubic meters per backwashing.

Process Demonstration

FRP Valveless Filter Tank Design Data